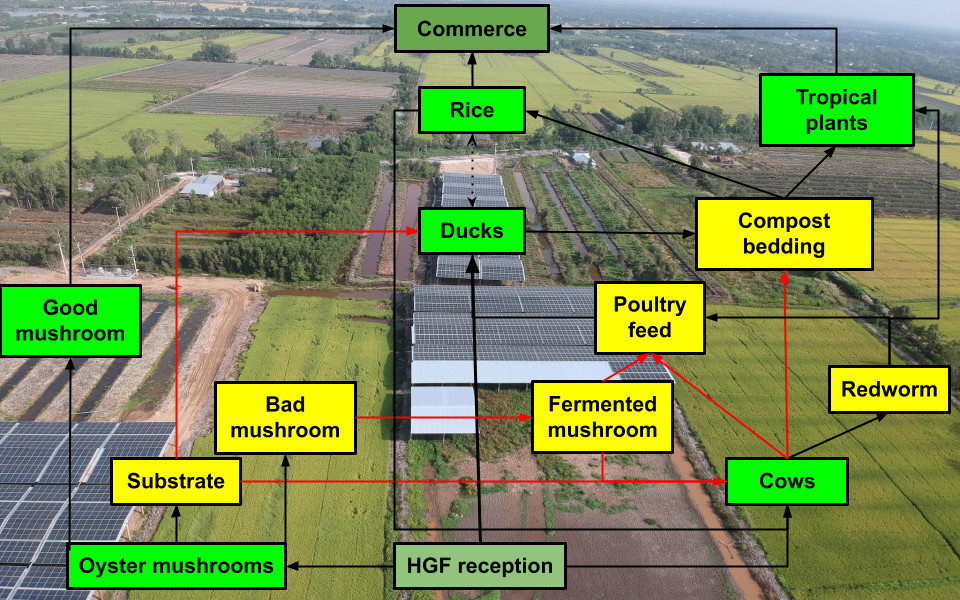

HG FARM’s closed-loop farming model “Mushroom – Cow – Duck – Rice – Electricity” in Hau Giang Province

Under the authority of making the circular agriculture model(s) successful, the Science – Technology – Engineering – Mathematics (STEM) model is essential equipment to be applied; in other words, professionalized agriculture is a key criterion in producing a continuous flow of energy and matter inside the farm.

Thus, the closed-loop farming model “Mushroom – Cow – Duck – Rice – Electricity” of HG FARM Limited Liability Company (HGF), located in the acid sulfate soil area in Hau Giang Province, is a notable example of optimizing material flow and delivering environmental benefits, along with acclimating to climate change and generating economic benefits.

Photo 1. HG FARM closed-loop farming: Mushroom – Cow – Duck – Rice – Electricity on the acid sulfate oil area in Hau Giang

Notes:

- Green: Main products;

- Yellow: By-products;

- Black arrow: Traditional approach;

- Red arrow: Applied waste transformation

General introduction to HGF’s product chain:

- Mushroom product chain:

– Objective: Produce and commercialize oyster mushrooms on the Can Tho market.

– Input: Momentarily, HGF does not manufacture mushroom substrates directly; We need to import the substrates from our local suppliers, and use well water and/or rainwater to stimulate fungal growth.

– Output includes 04 products:

(1) Oyster mushrooms for humans;

(2) Fermented oyster mushrooms for cattle;

(3) Poultry foods;

(4) Bedding.

– Optimizing material flow in the oyster mushroom production chain: mushrooms that do not meet market requirements will be transformed into the fermented mushroom for cattle and poultry feed for ducks. Furthermore, residual substrates will be repurposed as the bedding.

- Cow product chain:

– Objective: Raise F1 cows to produce F2 calves commercially and exploit their excrement for closed-loop farming.

– Input: three cow breeds (i.e., Lai Sind, Charolais, and Angus) were purchased in the local market, and the grass source from abandoned land is being utilized; Concurrently, HGF also uses elephant grass grown by HGF fertilizer (e.g., fresh cow manure, vermicompost, and compost bedding) within the farm’s premises.

– Output includes 03 products:

(1) Fresh cow manure;

(2) Compost bedding;

(3) F2 calves.

– Optimizing material flow in the cow-breeding chain: fresh cow manure is transformed into vermicompost and poultry feed; Meanwhile, cow urine will convert the residual substrate into the livestock bedding. Ultimately, the biomass that cows do not eat will be used as compost.

- Duck product chain:

– Objective: The male ducks will be sold for meat, and the female ducks will be kept to collect duck eggs.

– Input: Three duck breeds (i.e., Siamese, Dutch, and CV) were purchased at the local incubator; In the first two weeks of incubation, the industrial feed was used (i.e., Con Co C662), and in the later stage, mainly fermented poultry feed from oyster mushrooms and fresh cow manure was used.

– Output includes 03 products:

(1) Duck’s egg;

(2) Compost bedding;

(3) Male duck meat.

– Optimizing material flow in the chain of duck breeding within the bedding: Duck manure is converted into compost bedding and organic fertilizer for rice fields. Ducks’ energy will be expended on the field, capturing worms/butterflies, snails, and hoppers.

- Rice product chain:

– Objective: To produce and commerce “following nature” rice according to the Rice-Duck model.

– Input: The ST25 rice variety is purchased from Soc Trang and uses rainwater that was collected from 03 MW of HGF’s rooftop solar energy.

– Output includes 03 products:

(1) ST25 rice;

(2) Rice straw;

(3) Bran.

– Optimizing the flow of materials in the “following nature” rice farming chain: The rice fields are being protected by their natural enemies, the ducks; As well as the freshwater source, which is rainwater, is fully utilized without the need to use water pumps from the rivers/creeks. Cultivation of rice in the direction of following nature’s behaviors; In other words, only duck manure was present in the HGF rice field.

The exceptional value of the whole chain from raw materials and energy circulation: no organic ingredients are left behind on HGF farms. Prioritize the need for transformation into animal feed first, then fertilizer later, in favor of optimizing the energy in biomass. Similarly, the entire closed-loop recirculating farm is being operated with only two staff (i.e., the manager and operator).

Besides, the Mushroom – Cow – Duck – Rice – Electricity model helps HGF reduce input costs for green energy and even organic agricultural materials. “Vegetables in the morning, waste in the afternoon” is a painful truth of the agricultural-and-food production chain in the Mekong Delta. Mushroom products that do not meet the requirements of the market are fermented by HGF into probiotics, to help stimulate the digestive system and strengthen the immune system of cows and ducks. Therefore, HGF does not have the need to buy veterinary drugs, except for vaccines, and can economize on our opportunity costs in animal husbandry. Yet, the transformation of cow manure into poultry feed has significantly saved industrial feed resources for HGF. Lastly, ducks raised in our rice fields helped us not need to use pesticides, snail-killing products, or fertilizers.

A typical example of the uniqueness of the HGF closed-loop recirculating farm is as follows: Instead of using cow manure to raise earthworms and then using the earthworms to feed poultry, vermicompost is then used to fertilize plants. HGF will form poultry feed by combining fresh cow manure with digestive enzymes, which are fermented from qualified but deformed mushrooms. Simultaneously, cow manure and cow urine permeated the bedding, which is composed mainly of oyster mushroom substrates and will be used to raise earthworms. Once the source of agricultural supplies such as feed and fertilizer is self-controllable within the company, closed-loop farming at HGF will run smoothly with no emissions, waste, odors, or being influenced by market trends such as the paradox of plenty, which states that “a large harvest tends to bring low revenue to the farmers.” HGF’s ducks will grow by ingesting fermented feed from fresh cow manure at the cost of only one-third that of industrial feed. And duck manure, along with the compost bedding, will be used to fertilize the “following nature” rice fields. After the rice is harvested, the rice straw and bran will be repurposed for feeding breeding cows and converted into oyster mushroom substrates. Correspondingly, cows will consume biomass in the making of tropical fruits and vegetables.

Photo 2. Oyster Mushroom Substrate

- Substrates required to make cow bedding with a thickness of 30 cm in a 65 m2 area: 20.000 substrates;

- Substrates required to make duck bedding with a thickness of 03 cm in 36 m2: 200 substrates;

- The amount of compost bedding produced per day by 10 cows’ urine: 200 kg;

- Each cow consumed 15 kg of silage or 25 kg of forage, yielding 9 kg or 18 kg of fresh manure, respectively.

- In pursuance of 100 commercial mushrooms, which is equivalent to converting 30 kg of uncommerciable mushrooms into the fermented oyster mushroom;

- Economical: HGF converts byproducts from mushroom cultivation and cow husbandry into poultry feed at 35% of the cost of industrial feed.

- Environment: Microbial communities in the fermented mushroom strengthen the digestive system of cows, thereby inhibiting the production of methane gas (CH4) and contributing to diminishing global warming. HGF maximizes the use of rainwater that is collected from our solar rooftop for agricultural purposes.

- Society: A team of young engineers with a farming method that does not leave anything behind in agriculture has always been and will always be inspiring the rural area in Hau Giang Province or the Mekong Delta.

Ultimately, HGF builds a closed-loop recirculating farm on the basis of the following criteria: No waste, no wastewater, no emissions, no flies – mosquitoes – cockroaches, and no hostile personnel.

Under the authority of making the circular agriculture model(s) successful, the STEM model; In other words, professionalizing agriculture plays a crucial role in creating a continuous flow of energy and matter inside the farm. Hence, professionalization has helped HGF develop the farming chain, improve productivity, reduce energy loss, and limit waste. In summary, circular agriculture has been helpful for HGF to diversify or provide a wide range of products for consumers, as well as to be independent of resources such as acid-contaminated soil and rural labor.