Rieckermann Vietnam & BoReTech: Breakthrough Solution for PET/PP Tray Recycling

Rieckermann Vietnam & BoReTech: Breakthrough Solution for PET/PP Tray Recycling

BoReTech is a pioneering company in recycling technology, successfully developing multiple bottle-to-bottle solutions that meet international standards, including:

- PET bottle-to-PET bottle recycling, achieving food-grade quality, meeting the requirements of global beverage brands.

- HDPE bottle-to-HDPE bottle recycling for the personal care and home care sectors, ensuring high material efficiency and purity.

Rieckermann Vietnam, a leading provider of machinery and technical services from Germany, partners with BoReTech to introduce advanced plastic recycling solutions and technologies to the Vietnamese market.

Nextek said that the UK consumes 210,000 tons of food-grade PP per year. In comparison, China generates an average of about 1.5 million tons of plastic tray waste annually. There are 250,000 tons of waste disposable lunch boxes to be recycled, accounting for only 1% of all plastic waste that is recycled. Compared with the mature technology and experience of PET bottle recycling, there are still common technical difficulties in large-scale PP lunch box recycling applications. Currently, the recycling rate of PP lunch boxes worldwide is generally low, and there is a potential market.

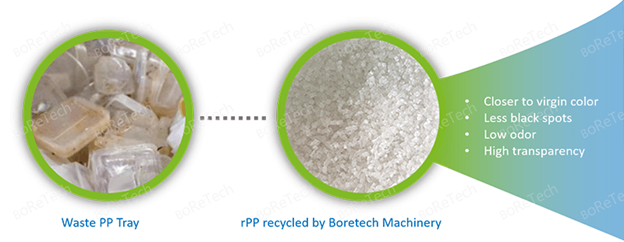

In 2021, BoReTech provided a 2000 kg/h PP tray washing line for local customer RE-MALL. The PP recycling line has been successfully operating for half a year, producing high-quality recycled PP pellets, helping RE-MALL take “purer, more stable, more environmentally friendly and safer” as the product concept, and practice the mission of promoting plastic recycling through technology and innovation to protect and purify our environment.

Relying on the R&D advantages and production experience of BoReTech, and the customer’s professional polymer background support, this project solved the PP hot washing problem of suspension, removed the rPP odor, and reduced the PP fines during the production to enhance the PP yield rate. The recycled PP quality from this system is positioned as a high-value application with high-quality characteristics, fewer black spots, lower odor, and high transparency. It has been used in high-end application markets such as daily chemical packaging, auto parts, and non-woven fabrics to enhance the market competitiveness for the customer.