CIRAC

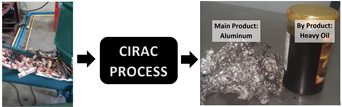

The CIRAC system turns aluminum laminated thermoplastic, focusing on snack and food packaging, into valuable products and materials, such as aluminum, diesel fuel and activated carbon. With the unique design of the CIRAC reactor, combined with the right pyrolysis conditions, we are able to separate the aluminum film from the waste while the remaining plastic is converted into liquid fuel (called heavy oil) – going from waste to valuable resources.

CIRAC provides a solution for converting aluminum laminated thermoplastic waste into these valuable products:

Aluminum (Ready)

Diesel (In development)

Activated Carbon (Concept)

The CIRAC process not only cuts aluminum production cost to a third of conventional mining, but also saves on the cost and environmental impacts of landfill, incineration and extraction activities.

We are currently developing new technologies for upgrading heavy oil outputs, and in the near future, will provide three valuable products – aluminum, diesel fuel, and activated carbon.

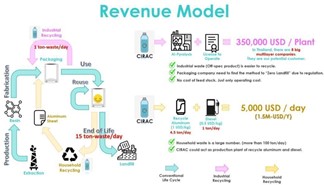

Currently, the system can produce about 300 kg of aluminum from 1 ton of waste packaging, per day. Recycled aluminum fetches about USD 1 per kg, while our operating cost is about USD 0.2 per kg. This means a profit of about USD 0.8 per kg and an estimated daily profit of USD 240.

Revenue streams:

Selling our products – aluminum, diesel fuel, and activated carbon;

Selling technology (CIRAC).

Selling service for recycle packaging waste